Semua produk

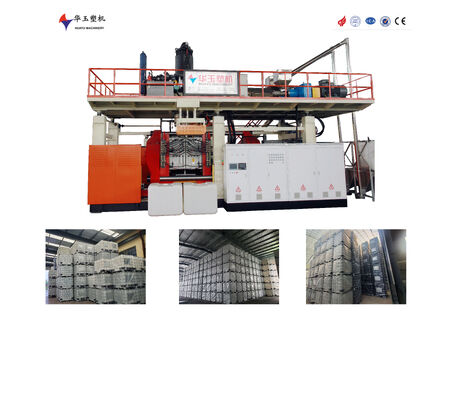

3000L 10-Layer Co-Extrusion Water Tank Blow Molding Machine with PLC Control System

Hubungi saya untuk sampel gratis dan kupon.

Ada apa:0086 18588475571

Wechat wechat: 0086 18588475571

Skype: sales10@aixton.com

Jika Anda memiliki masalah, kami menyediakan 24 jam bantuan online.

xDetail produk

| Sistem Kontrol | Plc | Bahan cetakan | Aluminium |

|---|---|---|---|

| Diameter sekrup | 80/80/80/80/80/80mm | Dimensi mesin | 10*5.5*7m |

| Konsumsi Rata-Rata | 180kw | Sakelar udara | Schneider |

| Rongga cetakan | Tunggal/ganda | Tekanan udara maksimum | 0.8Mpa |

| Die Head Weight | 26T | Bahan yang Berlaku | HDPE |

| Daya rata -rata | 540KW | Level Otomasi | Sepenuhnya otomatis |

| Kekuatan | 138kW | Laporan Tes Mesin | Asalkan |

| Inverter | Siemens | ||

| Menyoroti | 3000L Capacity Water Tank Blow Molding Machine,10-Layer Co-Extrusion Blow Molding Machine,PLC Control System Water Tank Molding Machine |

||

Anda dapat mencentang produk yang Anda butuhkan dan berkomunikasi dengan kami di papan pesan.

Deskripsi Produk

3000L 10-Layer Multi-Functional Water Tank Blow Molding Machine with Recirculating

This versatile 3000L capacity blow molding machine with 10-layer co-extrusion is engineered for producing a diverse range of plastic products. The integrated water tank system provides continuous, efficient cooling to minimize downtime and maximize production efficiency. With its multi-functional design accommodating various product shapes and sizes, this machine serves multiple industries. The user-friendly interface and automated controls ensure straightforward operation, while the durable water tank design offers easy maintenance and long-term reliability.

Auto Feeder System

| Component | Specification | Features |

|---|---|---|

| Hopper material | Stainless steel | Stable performance, easy maintenance |

| Feeding type | Vacuum loaded | |

| Feeding motor | 2.2/2.2/2.2kw |

Extrusion System Specifications

| Component | Specification | Features |

|---|---|---|

| Screw diameter | 130/150/130mm | Nitrided 38CrMoAIA |

| Screw L/D ratio | 28:1 | Special designed screw ensures uniform material plasticizing and efficiency |

| Extruder motor | 110/132/110kw | |

| Reducer | 375/420/375 | Premium Chinese brand offering long life and low noise operation |

| Screw heating power | 5.5kw*16 | |

| Plasticizing capacity | 1000kg/h |

Rekomendasi Produk